Zotera Radius Smart RTU™

A Smart Pumping Station that leverages the motor and power panels of existing pumping stations for Oil & Gas pipeline pumping stations, Water Management Lift Stations , and others…

The Zotera Radius Smart RTU™ can diagnose problems and conditions of the pumping station & advise the SCADA controls. It offers predictive diagnostics of sensors, pumps, and physical network, and provides a Smart Motor Control System, monitors temperature, current draw, and reports anomalies.

- Allows a “Smart Upgrade” while maintaining the infrastructure investment.

- Enables an easy migration to a more predictive system infrastructure.

- Programmed for a duplex lift station and enabled to work with predefined smart devices and sensors.

- Provides a Smart Tank system with tank level and velocity of flow, alerting based on threshold settings.

- Offers Custom Face Plate HMI Templates for easy use and diagnostics access.

- Built in ADC Automatic Device Detection for discovery and setup of failed devices.

- Includes Stratix Switch with Allen Bradley Industrial tools and Cisco network toolkit for remote support.

Operational Visibility

- Predictive monitoring of pump health

- Early Warning & Diagnostics of mechanical failures

- Fact-based decision making using real-time diagnostic information

- Local management of process in the event of network issues

- DeviceLogix™ allows for decentralized intelligence and reduces unnecessary network traffic

Business Value Delivered

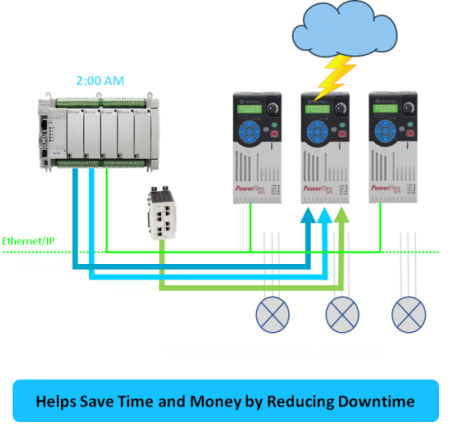

- Minimize Production Downtime

- Can help to minimize cost due to controlled shutdown

- Opportunity for Predictive rather than reactive maintenance

- Help protect critical assets from costly failures

Zotera Radius Smart RTU™

A Smart Pumping Station that leverages the motor and power panels of existing pumping stations for Oil & Gas pipeline pumping stations, Water Management Lift Stations , and others…

The Zotera Radius Smart RTU™ can diagnose problems and conditions of the pumping station & advise the SCADA controls. It offers predictive diagnostics of sensors, pumps, and physical network, and provides a Smart Motor Control System, monitors temperature, current draw, and reports anomalies.

- Allows a “Smart Upgrade” while maintaining the infrastructure investment.

- Enables an easy migration to a more predictive system infrastructure.

- Programmed for a duplex lift station and enabled to work with predefined smart devices and sensors.

- Provides a Smart Tank system with tank level and velocity of flow, alerting based on threshold settings.

- Offers Custom Face Plate HMI Templates for easy use and diagnostics access.

- Built in ADC Automatic Device Detection for discovery and setup of failed devices.

- Includes Stratix Switch with Allen Bradley Industrial tools and Cisco network toolkit for remote support.

Operational Visibility

- Predictive monitoring of pump health

- Early Warning & Diagnostics of mechanical failures

- Fact-based decision making using real-time diagnostic information

- Local management of process in the event of network issues

- DeviceLogix™ allows for decentralized intelligence and reduces unnecessary network traffic

Business Value Delivered

- Minimize Production Downtime

- Can help to minimize cost due to controlled shutdown

- Opportunity for Predictive rather than reactive maintenance

- Help protect critical assets from costly failures